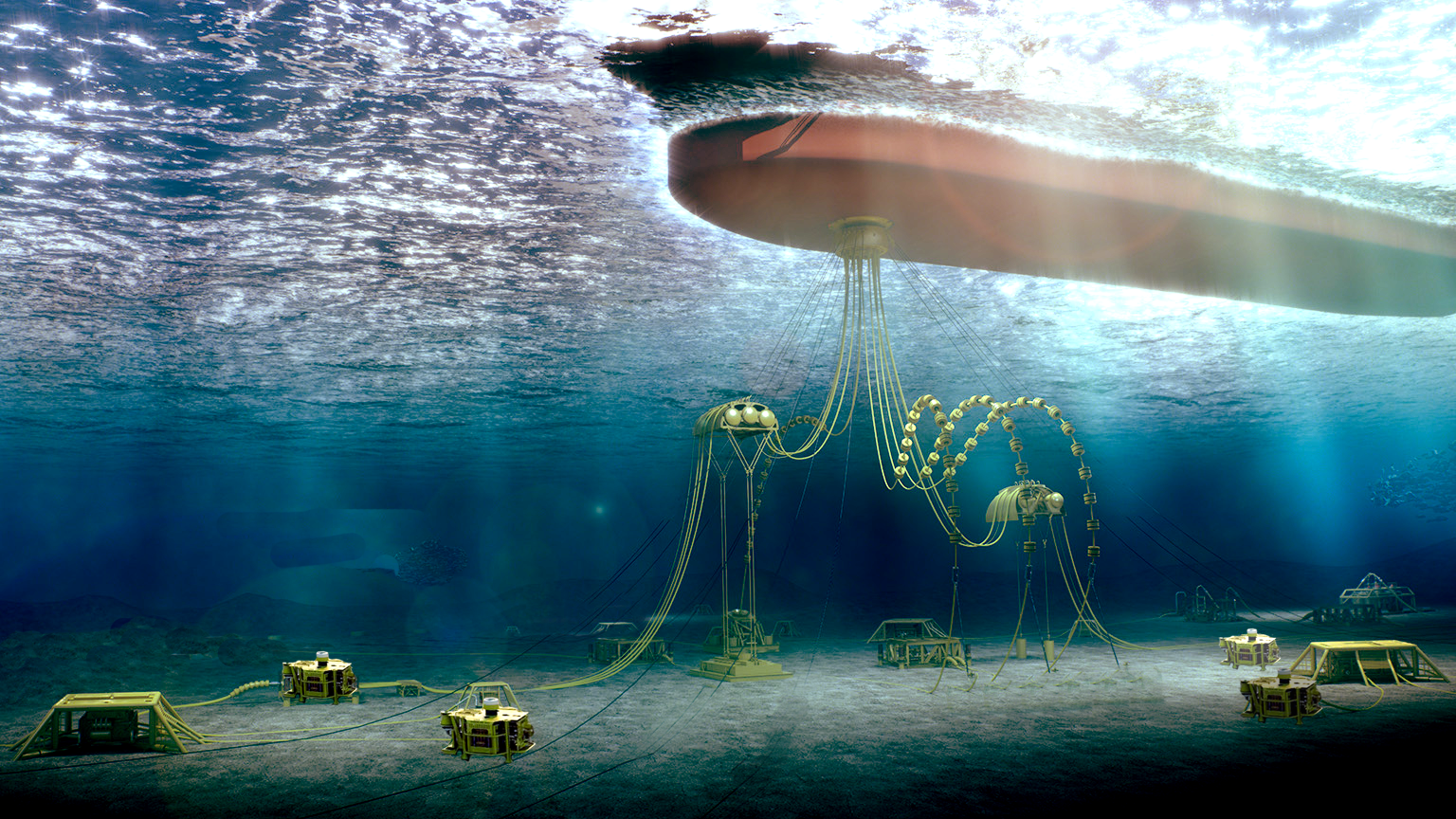

Unlocking the value of data

Subsea Operational Intelligence Services

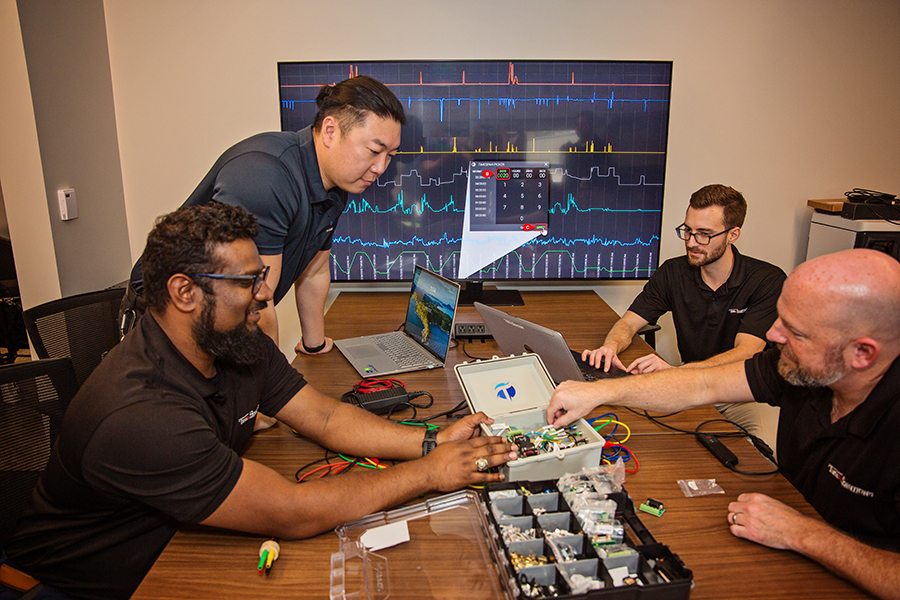

We offer subsea operational insight as services. Our network of subject matter experts establish fit for purpose surveillance programs.

We remove the burden of implementing and maintaining data tools so our clients can focus on plant safety, efficiency and up-time.

Our SharpWatch® Real Time Condition Monitoring Framework automates anomaly detection and leverages a patent pending machine learning algorithms to continuously improve.

We transforming data into decisions

Subsea production facilities generate data that is rarely leveraged to improve safety, integrity, or to identify emerging risks. We offer a paradigm shift to Subsea operations through implementation of our automated data analytics and operational intelligence services.

We bridge the gap and carry the ball

Integrating IM data and operations is a difficult gap to overcome. Our team of subsea specialists implements surveillance programs to transform data into actionable information. We maintain tools and filter erroneous indicators to reduce downtime and improve safety and operability performance.

Standard Service Features

Features available are dependent on installed sensors and data availability.

- Real time or Historical Condition Monitoring

- Alerts through text or email based on Process Upsets

- Pump Performance and Degradation Detection

- Hydraulic Leak Detection

- Erosion and Corrosion Monitoring

- Electrical and Communication Health monitoring

- Process deviations & Anomaly Detection

- Sensor Availability and Drift Detection

- Anomaly Case File Management

- Electronic Thermal Monitoring

Advanced Service Features

Advanced features are available but vary depending on the type of plant being monitored. Please contact us for information on our advanced service features.

Benefits of Condition Monitoring

- Allows operations teams to be more in touch with the plant leading to improved up time

- Reduced unplanned interventions

- Minimizes escalation of failures that result in loss of output

- Proactively informs management of impending equipment failure to aide in forecasting

- Provides additional data to inform risk analysis

- Identifies leading indicators which reduce the amount of potential undetected failures

- Allows for deeper understanding of failures which aides in troubleshooting, root cause failure analysis

- Provides performance data that can be used for continuous improvement of future equipment

Custom Subsea Data Tools

We invest in data analytical techniques and models that are directly applicable to subsea production systems.

The SharpWatch® Real Time Condition Monitoring system contains libraries of data models that transforms your data into actionable information and highlights emerging risk.

Ready to deploy SharpWatch® on your asset ?